Strategically fitted fixed monitors are also helpful to supplement the rim seal system.

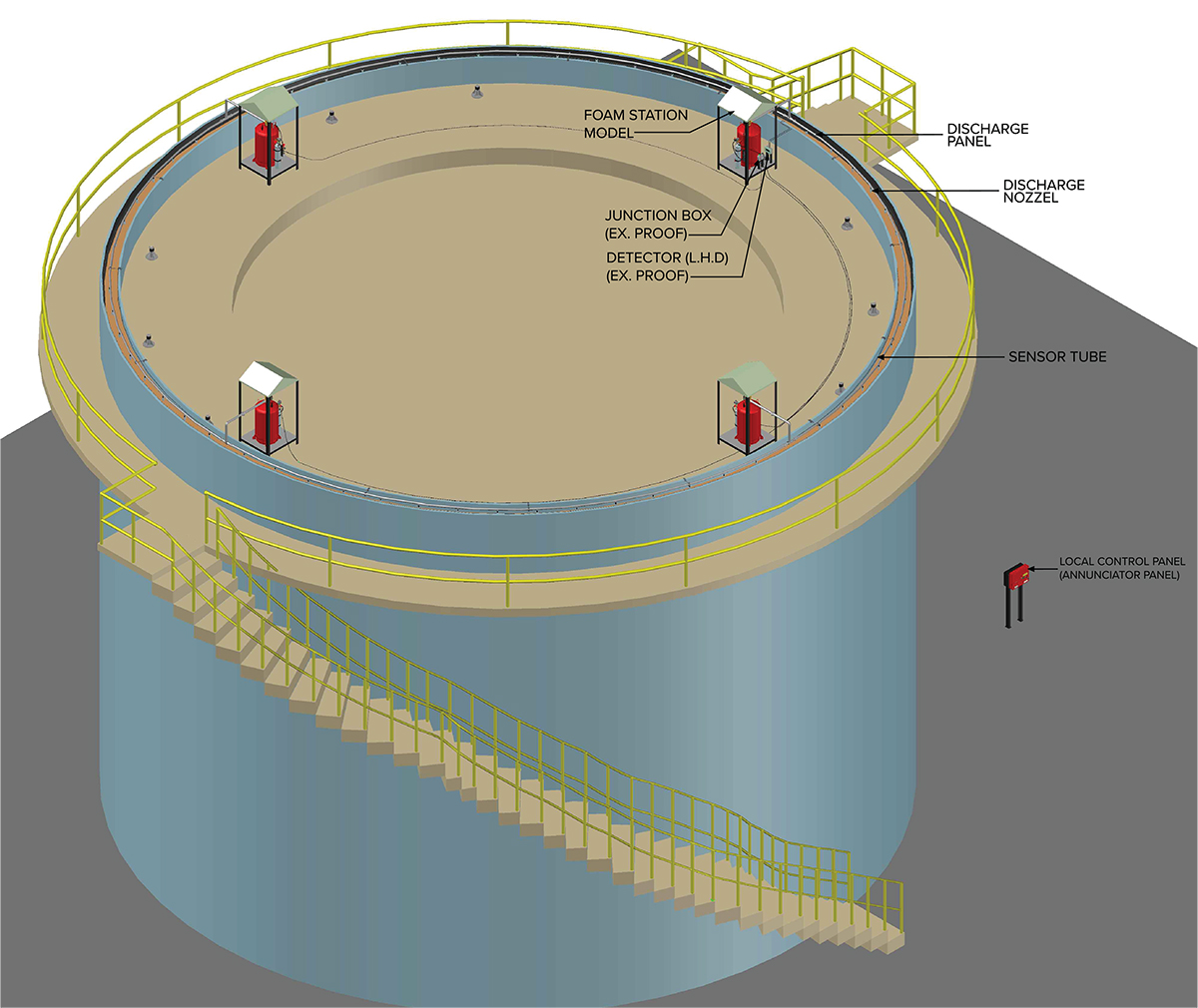

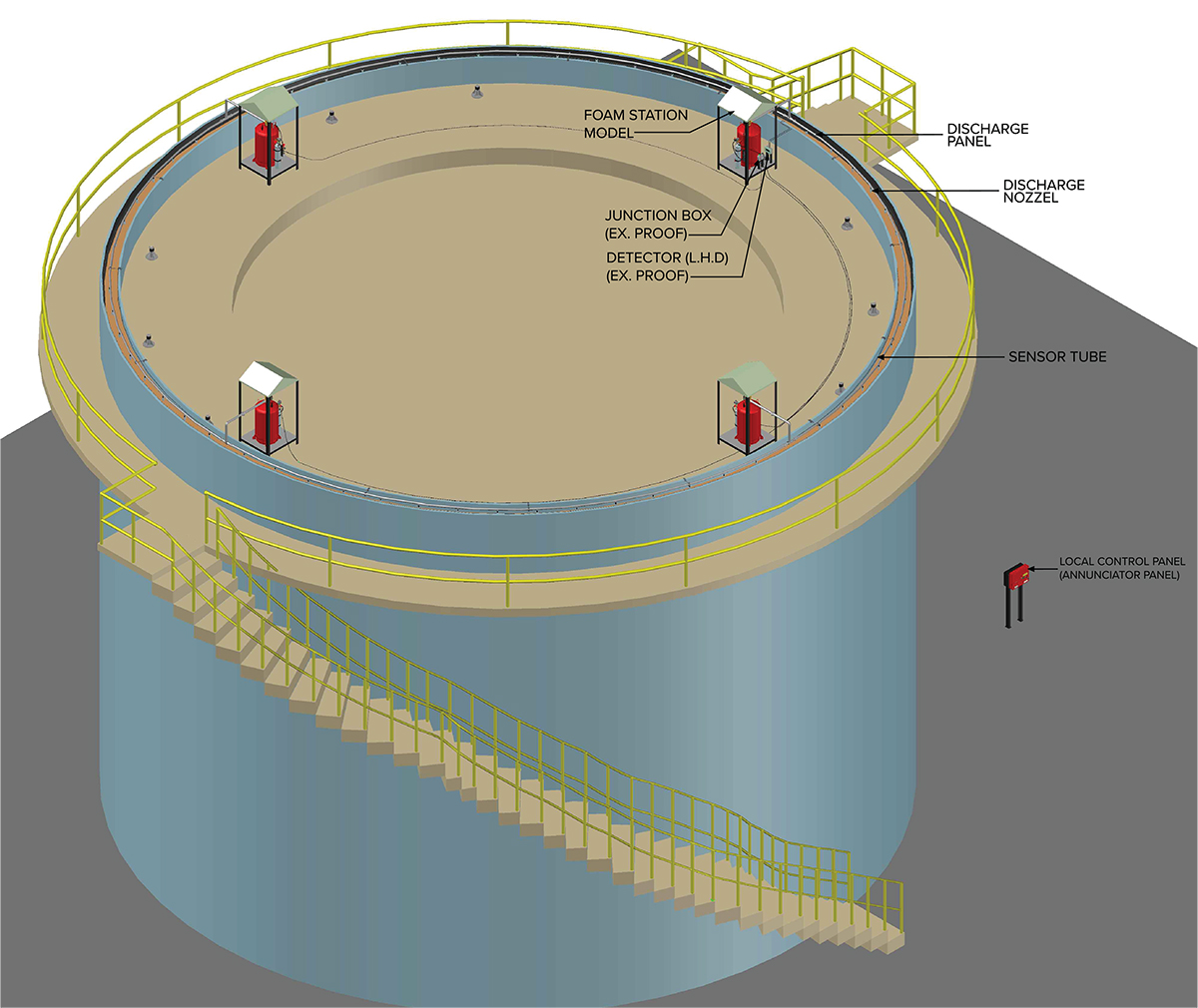

Rim seal protection system floating roof tanks.

The tank has a cone roof but with the addition of an internal floating roof or pan that floats directly on the fuel surface.

Hmt offers a full line of primary and secondary seals for both internal and external floating roof tanks.

Hmt seal systems are customized for each specific tank with a variety of configurations component sizes and material options available to handle any application and stored product.

It consists of stainless steel circular piping with glass bulb detectors sprayers installed in the rim seal area on the floating roof pontoon of the storage tank.

The design needs to be wind resistance.

Specially designed and manufactured for quick detection and extinguishing of any rim seal fires as per the national international safety standards.

The system is a combined detection and extinguishing system.

The rim seal covers the space between the floating roof and the tank shell side wall.

Automatic rim seal fire detection protection system floating roof tanks are one of the safest ways of storing very large quantities of hydrocarbons but because of location in isolated areas they are prone to lightning strikes also fires due to static electricity are likely.

Hmt seals are well known as leading the industry in design quality craftsmanship durability and non.

Early detection is necessary to reduce loss.

The extinguishing media is premix foam solution which has excellent film formation cooling properties to prevent re ignition after suppression.

Sometimes it becomes tough to detect a fire in rim seal system especially when the floating roof is at its lowest level.

The shootfire branded rim seal fire protection system for floating roof fuel storage tank is a fully automatic fire detection cum suppression system.

The above rim seal fire protection system is successfully operating in huge number of floating roof storage tanks of various sizes from 20 meter dia up to 79 meter dia at refineries oil terminals process plants etc.

The solutions available are several and each one is designed to cope with a specific tank seal design fuel content and environmental condition.